Fostering Field of Vision: How to Increase Supply Chain Visibility

Ready to increase your supply chain visibility?

Improve your field of vision with Magaya.

Two years ago, supply chain challenges rarely — if ever — made the news. Now, reports of ongoing issues and potential delays are commonplace as the market comes to terms with a “new normal” defined by ultra-large container ships, shocking levels of port congestion, and rapidly-evolving import and export regulations.

The result? Visibility equals value. Increased insight into supply chains from start to finish provides a competitive edge for companies looking to drive sustainable success. The problem? Current conditions conspire to make achieving this visibility a challenge. To foster a functional field of vision, companies need a new approach to supply chain management. Here’s what it looks like in practice.

Key Takeaways

- Unexpected interruptions in the movement of goods worldwide are now par for the course, but partners and customers aren’t interested in how and why these problems are impacting operations — they just want to know what’s happening, why their products are delayed, and when they’ll actually arrive.

- Visibility blind spots can lead to excessive calls and emails from frustrated customers, cost overruns, and reputation damage.

- Magaya has solutions to increase visibility across internal teams, external agents and carriers, and customers.

Current Challenges in Supply Chain Sightlines

While the adoption of digital tracking technologies has made it possible for manufacturers, shippers, and importers to see the start and end of supply journeys worldwide, these sightlines often get fuzzy in the middle.

The primary problem? Port congestion. Headlines about port backups continue to make the rounds, and shipping group Maersk says that customers should continue to expect port delays for the foreseeable future. The company notes that ports on the U.S. West Coast now have waiting times between 38 and 45 days and while there’s hope in Europe — the Port of Antwerp is on track to reduce wait times from 10 days down to 2 — China’s Yantian terminal is now restricting the acceptance of containers to help ease port congestion.

COVID-19 outbreaks are also causing both production and shipping issues as factories and logistics providers struggle to keep operations up and running with minimal staff. From front-line workers to delivery drivers to port cargo handlers, unexpected outbreaks are creating ripple effects in supply chains that are difficult to predict — and even more challenging to manage.

Beyond staff and shipping issues, many companies are still dealing with legacy processes that aren’t capable of keeping pace with evolving supply chain expectations. These include paper-based inventory management and shipping processes that are disconnected from online dispatch portals, in turn creating a gap between what companies know and what customers want. These familiar functions are also hard to dislodge; while digital systems offer increased performance, companies need tools and technologies that are quick to deploy, simple to integrate, and easy for employees to use.

The end result is that, even when armed with digital tracking tools, visibility remains a challenge. Unexpected interruptions in the movement of goods worldwide are now par for the course, but partners and customers aren’t interested in how and why these problems are impacting operations — they just want to know what’s happening, why their products are delayed, and when they’ll actually arrive.

Here’s Why You Should Fear Being in the Dark

If supply chains go dark during the journey from producer to logistics provider to freight forwarder and eventual receiver, there can be negative impacts at many levels.

First are consumer frustrations. If customers place orders with expected ship and receive dates, they want answers around why these dates haven’t been met — even if companies ultimately have minimal control over supply chain forces.

Many freight forwarders are finding themselves inundated with calls and emails around supply chain delays, all asking for answers. This creates a dual problem: Staff simply can’t respond to every message as it arrives, and in many cases, the only information they can provide in response is “we don’t know.” Here, lacking visibility can drive down perceived business value.

Companies may also see increased costs from being in the dark. Consider a large-volume order that’s produced and shipped on time but suddenly falls off the radar when it reaches port. As delays drag on and no updates are forthcoming, customer complaints rise. In response, the company remakes and reships the order with a different carrier service and route to ensure client satisfaction. Not long after the replacement order arrives, the original shipment also clears supply chain hurdles and appears on the customer’s doorstep. Understandably, they’re unwilling to pay for a duplicate order and so companies must shoulder the cost.

Limited visibility can also lead to long-term reputation damage. Here’s why: If shipments are occasionally lost or misplaced in post-pandemic supply chains, customers are likely to offer some leeway. If these issues become regular occurrences, however, even long-term clients will start looking for other providers better equipped to provide ongoing information about where their shipments are, what’s holding them up, and how long it will take.

Boosting Visibility – and Value – With Magaya

It’s time for a new approach to supply chain visibility. While most customers have come to accept that supply chain delays are inevitable these days and are willing to make some accommodations for these challenges, they can’t afford to be left in the dark — if shipments won’t make it on time, they still need to see what’s happening (or isn’t) so they can make alternative arrangements and keep operations on track.

Magaya can help boost supply chain visibility across three key areas:

- Customer experience

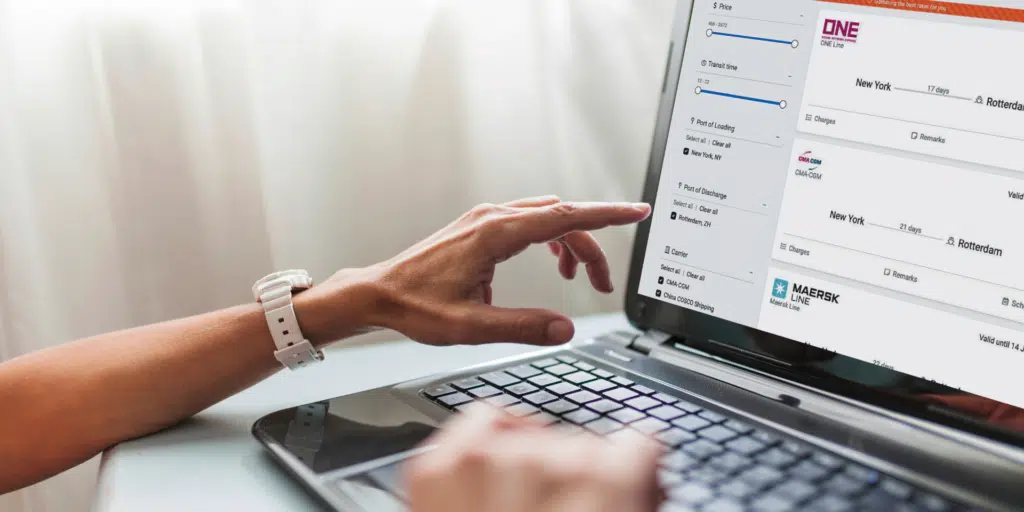

Visibility in isolation isn’t enough — customers want a freight forwarding experience that meets their needs end-to-end. The Magaya Digital Freight Portal offers online quotations, on-demand schedules, instant booking notifications, and 360-degree visibility into shipping from the moment goods leave suppliers to their last-mile delivery. By providing a robust and responsive digital experience, your team is better equipped to handle concerns when they do arise and customers are better equipped to find the data they need by themselves, whenever they need it.

- Container tracking

Manually tracking and updating carrier information is both time- and resource-intensive. Keeping up with container progress worldwide introduces the potential for both duplicate data entry and data entry errors, in turn making it harder to provide accurate and on-time information to customers. The Container Tracking extension for Magaya Supply Chain offers a better way.

It starts with hyper-accurate visibility — know where containers are, anytime, and anywhere in the world. The Magaya platform also makes it possible to link container information in shipments to your container tracking sources worldwide to streamline the process of finding and tracking key product and delivery data. Even better? The solution supports more than 100 ocean carriers, with more added every week, and tracking data from any source can be easily shared with customers.

- Connected logistics

The Magaya Digital Freight Platform takes tracking and visibility a step further by connecting your shipping and warehouse operations from end-to-end. By creating a single source of truth for all your product, container, shipping, and delivery data, Magaya helps you eliminate siloed data and ensure that all data is accurate, up to date, and applicable. The result? Increased visibility across your entire organization, from front-line staff to managers, stakeholders, and customers.

Seeing is Believing

Visibility into evolving supply chains helps boost customer confidence — if they can see where shipments are and what’s causing delays, they’re more likely to believe that your company is doing all it can to deliver goods on time. Without these sightlines, however, frustration mounts as clients struggle to reconcile orders in progress with current operations, in turn opening the door to potential customer churn.

Magaya freight forwarding solutions can help your company leverage the value of visibility. By providing end-to-end insight across customer experiences, container tracking, and connected logistics, Magaya can help your company see what matters, when it matters most.

Ready to increase your supply chain visibility?

Improve your field of vision with Magaya.